An effective oil spill kit is essential for managing spills and preventing environmental damage. Key components...

How to Choose the Right Spill Kit: A Comprehensive Guide for Workplace Safety

Whether you run a small workshop or a big industrial plant, you really should be ready for unintentional spills. But given the abundance of choices available, how can you decide on the correct spill kit for your requirements? Let's explore the realm of spill kits and ensure you are ready for everything that might present itself.

Understanding Spill Kits: More Than Just Cleanup Tools

First of all, just what is a spill kit exactly? All told it's a set of tools and supplies meant to quickly contain, absorb, and clean spills. The reality is, though, that not all spill kits are made equally. Each suited to particular circumstances and drugs, they come in many different forms, sizes, and configurations.

Types of Spill Kits: Finding Your Perfect Match

1. General Purpose Kits- These are your jack-of-all-trades kits, best for non-hazardous liquids such as coolants or water. For offices, classrooms, and general work environments they are fantastic.

2. Oil and Fuel Kits- Designed to handle hydrocarbon-based spills, garages, petrol stations and maritime settings all depend on these kits. Many times they have hydrophobic components that absorb oil but reject water.

3. Chemical Kits- These kits are your first choice whether handling acids, bases, or other dangerous compounds. Labs, factories, and any place handling corrosive materials depend on them.

Factors to Consider When Choosing a Spill Kit

Knowing the kinds now will help us to dissect what you should consider while choosing a spill kit:

1. Identify Your Risks

Sort of spills you probably will come across? Wander throughout your facility and note every possible source of a spill.

2. Volume Matters

Think of the biggest liquid bottle you find in your workplace. At least that much volume should be handled by your spill kit.

3. Compatibility is Key

Make sure the absorbents in your kit match the liquids you handle. A few compounds can react severely with some absorbents.

4. Location, Location, Location

Consider the places most likely to see spillage. various sectors of your company could call for various kits.

5. Regulatory Compliance

Research local, state, and federal rules on spill response in your sector. Your kit must either meet or surpass these criteria.

6. Ease of Use

You want simple-to-use and access equipment in an emergency. For bigger areas or fast access, think about wheeled kits or wall-mounted kits.

7. Training Requirements

The best one available is meaningless if your staff does not know how to run a kit. Think about including training in your decision-making process.

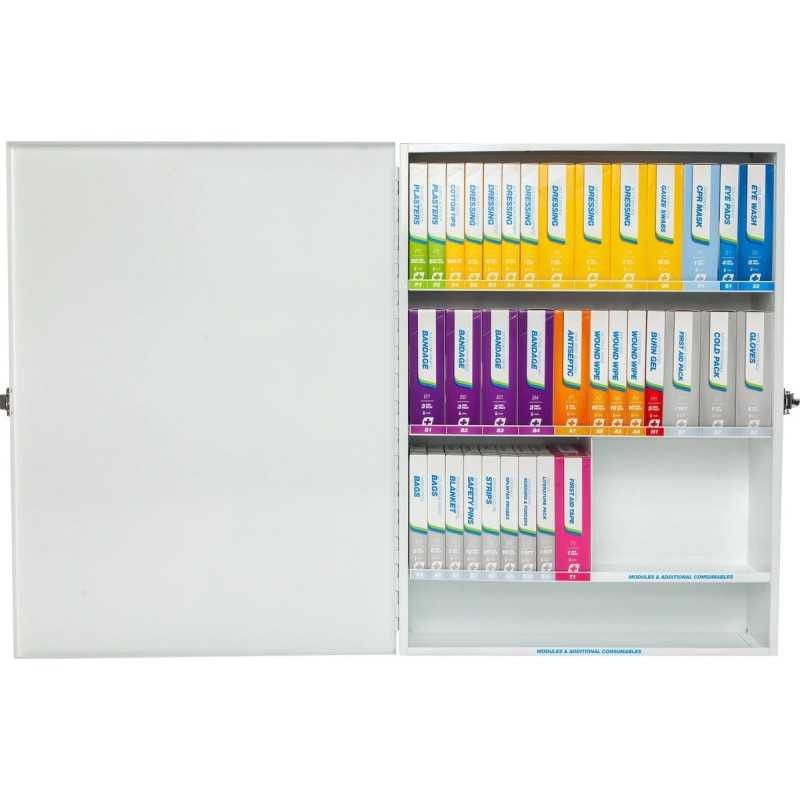

Components of an Effective Spill Kit

A well-stocked spill kit typically includes:

● Materials used in absorption

● Personal protective tools

● Tools for containment

● disposed of bags

● Cleansing tools

● explicit directions for application

Sizing Up Your Spill Kit Needs

From big-wheeled containers to small 5-gallon buckets, spill kits come in several sizes.

Here is a broad road map:

● Small: Perfect for small workshops or office minor spills

● Medium: Right for most small to medium-sized companies

● Large: Essential for industrial environments or locations prone to significant spill hazards

● Extra Large: For large-scale industrial locations with substantial spill potential

Customising Your Spill Kit

Sometimes off-the-shelf fixes just are insufficient. In these situations, give your spill kit some personalising though :

● Including particular absorbents for unusual substances you use

● Including specific instruments for your given surroundings

● Changing the material amounts depending on your risk assessment

Maintenance and Inspection: Keeping Your Kit in Top Shape

Having a spill kit is great, but maintaining it is crucial.

1. Regular Inspections

Monthly check your kits to make sure all parts are present and in good shape.

2. Replace Used Items

Restock any used resources right away following a leak.

3. Check Expiration Dates

A few things, including PPE, can have expiration dates. replace them as necessary.

4. Update as Needed

Your spill kit's needs will evolve as your workplace does. Review and upgrade your kits often.

Training: The Key to Effective Spill Response

Even the best spill kit is useless without proper training. Ensure your team knows:

● Where might one find spill kits?

● How does one evaluate a spill scenario?

● Correct use of every element of the kit

● Correct techniques of disposal

● When should I seek further assistance?

The Future of Spill Response

Spill kits change along with technology. Keep a look out for these developments:

● Intelligent sensors warn responders and identify spills.

● biodegradable, environmentally friendly absorbents.

● Training on augmented reality for response to spills.

Selecting the appropriate spill kit goes beyond merely fulfilling a safety compliance box. It concerns safeguarding your staff, company, and surroundings. You're investing in peace of mind when you thoroughly evaluate your demands, choose the right kit, and guarantee correct training and maintenance rather than only preparing for mishaps.

Regarding spills, it's usually wise to be over-prepared rather than caught off guard. Spend some time selecting the appropriate spill kit now to be ready for anything.

Leave a comment